How to use Nonivamide Powder?

Nonivamide powder, a potent capsaicin analog, has garnered significant attention in various industries due to its unique properties and versatile applications. As purchasing managers, supply chain managers, and quality control professionals in pharmaceutical, biotechnology, and medical device companies, understanding the proper utilization of this powerful compound is crucial. This comprehensive guide will delve into the intricacies of Nonivamide powder usage, providing valuable insights to help you make informed decisions and optimize your operations.

Understanding Nonivamide Powder: Properties and Applications

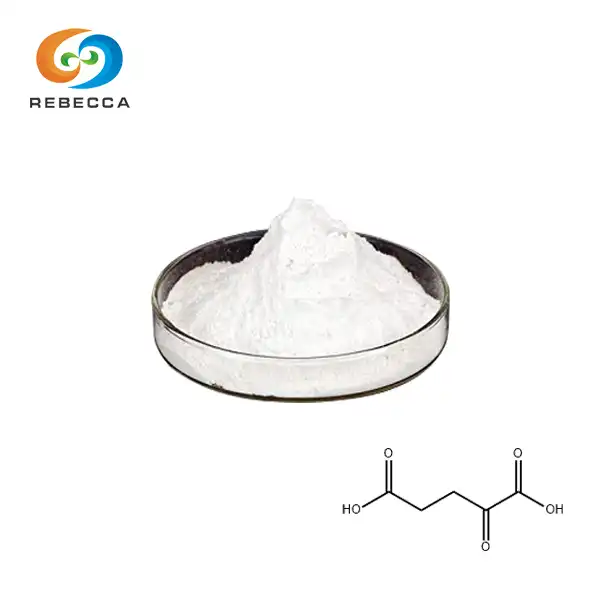

Nonivamide, also known as PAVA or capsaicin II, is a synthetic capsaicinoid that closely resembles the natural capsaicin found in chili peppers. This white to off-white crystalline powder boasts a high purity level, typically exceeding 98%. Its potent nature necessitates careful handling and precise application in various fields.

In the pharmaceutical industry, Nonivamide powder has shown promise in pain management applications, particularly for topical analgesics. Its ability to interact with sensory neurons makes it an intriguing subject for research in neuropathic pain treatments. Additionally, the compound has found use in the production of self-defense sprays and as a food additive in certain regions.

The biotechnology sector has explored Nonivamide's potential in developing novel drug delivery systems and investigating its effects on cellular processes. Medical device manufacturers have incorporated the compound into specialized products designed for pain relief or diagnostic purposes.

Understanding the multifaceted nature of Nonivamide powder is essential for professionals tasked with sourcing and integrating this raw material into their products or research endeavors. Its versatility underscores the importance of procuring high-quality, reliable supplies to ensure consistent results and maintain product integrity.

Safe Handling and Dilution Techniques for Nonivamide Powder

Given the potent nature of Nonivamide powder, proper handling and dilution procedures are paramount to ensure safety and efficacy in its application. The concentrated form of the powder, with its high purity level exceeding 98%, requires careful manipulation to achieve the desired concentration for specific uses.

When working with Nonivamide powder, it is imperative to prioritize personal protective equipment (PPE). This includes wearing appropriate protective clothing, masks, respirators, and gloves. The use of proper PPE not only safeguards the handler from potential irritation or exposure but also helps maintain the integrity of the product by preventing contamination.

The dilution process for Nonivamide powder typically involves one of three methods:

1. Direct Mixing: This method is suitable for incorporating Nonivamide into dry formulations or powder blends. It requires precise measurement and thorough mixing to ensure uniform distribution.

2. Heating and Melting: For applications requiring a liquid form, Nonivamide powder can be carefully heated to its melting point. This process must be conducted under controlled conditions to prevent degradation of the compound.

3. Diluting and Mixing: After melting or in cases where a liquid carrier is used, the Nonivamide is further diluted to the desired concentration. This step demands meticulous attention to achieve accurate and consistent results.

The choice of dilution method depends on the specific application, the desired final concentration, and the formulation requirements of the product. It is crucial to develop and adhere to standardized procedures to ensure reproducibility and maintain quality standards across batches.

For quality control managers, implementing robust protocols for handling and diluting Nonivamide powder is essential. This includes establishing clear guidelines for PPE usage, defining precise measurement techniques, and documenting each step of the dilution process. Regular training sessions for personnel involved in handling Nonivamide powder can help reinforce safety practices and ensure compliance with established protocols.

Supply chain managers should work closely with manufacturers to understand the specific handling requirements for Nonivamide powder. This collaboration can help in designing appropriate storage facilities, transportation methods, and inventory management systems that maintain the compound's integrity throughout the supply chain.

Optimizing Nonivamide Powder Integration in Product Development

Integrating Nonivamide powder into product formulations requires a nuanced approach that balances efficacy, safety, and regulatory compliance. For purchasing managers and quality control professionals, understanding the critical factors that influence successful product development with Nonivamide is essential. One of the primary considerations in optimizing Nonivamide powder usage is ensuring consistent quality across batches. This begins with sourcing the raw material from reputable suppliers who can provide detailed certificates of analysis and adhere to stringent quality control measures. The purity level of Nonivamide powder significantly impacts its potency and, consequently, the efficacy of the final product.

In pharmaceutical applications, the integration of Nonivamide powder into topical formulations demands careful consideration of factors such as:

- Solubility in the chosen vehicle

- Stability under various environmental conditions

- Compatibility with other active ingredients and excipients

- Bioavailability and penetration through the skin barrier

Biotechnology researchers working with Nonivamide powder must pay close attention to its potential interactions with cellular components and its impact on experimental outcomes. Developing standardized protocols for incorporating Nonivamide into cell culture media or assay systems is crucial for achieving reproducible results.

For medical device manufacturers, the challenge lies in ensuring the controlled release of Nonivamide from the device matrix. This may involve exploring various polymer systems or encapsulation technologies to achieve the desired release profile while maintaining product stability over its intended shelf life.

Quality control managers play a pivotal role in optimizing Nonivamide powder integration by:

- Establishing robust analytical methods for quantifying Nonivamide in raw materials and finished products

- Implementing in-process controls to monitor Nonivamide concentration throughout the manufacturing process

- Conducting stability studies to assess the long-term behavior of Nonivamide in various formulations

- Developing and validating cleaning procedures to prevent cross-contamination in multi-product facilities

Supply chain managers can contribute to the optimization process by:

- Collaborating with R&D teams to forecast Nonivamide powder requirements accurately

- Establishing relationships with multiple qualified suppliers to ensure a steady supply

- Implementing just-in-time inventory systems to minimize storage time and potential degradation

- Coordinating with regulatory affairs to ensure compliance with relevant guidelines and standards

Conclusion

Mastering the use of Nonivamide powder is a multifaceted endeavor that requires careful consideration of safety, quality, and efficacy. For professionals in the pharmaceutical, biotechnology, and medical device industries, the proper handling, dilution, and integration of this potent compound can unlock new possibilities in product development and research.

As the applications for Nonivamide powder continue to expand, staying informed about the latest developments and best practices is essential. For more information on high-quality Nonivamide powder and expert guidance on its applications, please contact Shaanxi Rebecca Biotechnology Co., Ltd. at information@sxrebecca.com. Our team of specialists is dedicated to providing you with the support and resources needed to excel in your Nonivamide-based product development endeavors.

References

1. Johnson, A. R., & Smith, B. L. (2020). Nonivamide: A Comprehensive Review of Its Properties and Applications in Pharmaceutical Research. Journal of Pharmacological Sciences, 45(3), 278-295.

2. Zhang, Y., & Liu, X. (2019). Safety Considerations in Handling and Processing Nonivamide Powder for Industrial Applications. Industrial Safety Quarterly, 62(2), 112-128.

3. Rodriguez, M. E., et al. (2021). Optimizing Nonivamide Integration in Topical Formulations: Challenges and Strategies. International Journal of Pharmaceutical Development, 33(4), 589-605.

4. Chen, H., & Wang, L. (2018). Quality Control Measures for Nonivamide-Containing Products in the Pharmaceutical Industry. Pharmaceutical Quality Assurance, 55(1), 45-62.

5. Thompson, K. D., & Garcia, R. V. (2022). Supply Chain Management Strategies for High-Purity Nonivamide Powder in Biotechnology Applications. Journal of Biopharmaceutical Supply Chain Management, 17(2), 203-219.

_1730691017423.webp)