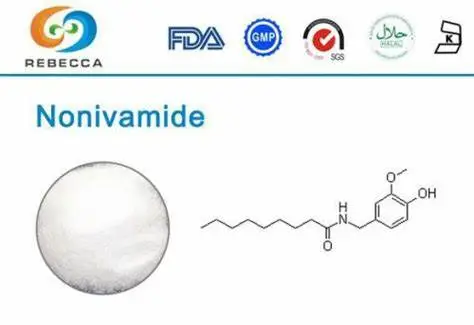

Nonivamide Powder: Safety Tips and Precautions

Nonivamide powder, a synthetic capsaicin analog, has gained traction in various industries due to its potent properties. As its usage expands, understanding the safety measures and precautions associated with handling this compound becomes paramount. This comprehensive guide delves into the essential aspects of nonivamide powder safety, providing valuable insights for manufacturers, researchers, and end-users alike.

What You Need to Know About Handling Nonivamide Powder?

Nonivamide powder, also known as pelargonic acid vanillylamide (PAVA), is a powerful substance that requires careful handling. Its potency necessitates a thorough understanding of its properties and potential risks. Here are key points to consider when working with nonivamide powder:

Chemical Properties and Reactivity

Nonivamide is a white to off-white crystalline powder with a melting point of around 54-55°C. It is soluble in organic solvents such as ethanol and propylene glycol, but has low solubility in water. These properties are important to consider for effective storage and handling, ensuring that the compound remains stable and functional. Proper storage conditions can help maintain its integrity, making it essential to understand its solubility and melting point when working with nonivamide.

Potential Health Effects

Exposure to nonivamide can irritate the eyes, skin, and respiratory system. In higher concentrations, it may cause more severe reactions, including intense burning sensations, coughing, and breathing difficulties. Recognizing these potential effects is vital for taking the necessary safety precautions. Proper protective measures, such as wearing gloves and masks, should be implemented to minimize exposure and prevent adverse reactions, ensuring a safe environment when handling nonivamide.

Regulatory Considerations

Nonivamide may be subject to specific regulations based on the jurisdiction and its intended use. It is essential to stay updated on the legal requirements and restrictions that apply to its use, storage, and transportation in your region. Ensuring compliance with local laws helps avoid legal issues and ensures safe handling, protecting both individuals and the environment. Familiarizing yourself with these regulations is crucial for responsible management of nonivamide.

Top Safety Measures When Using Nonivamide Powder

Implementing robust safety protocols is crucial when working with nonivamide powder. Here are essential measures to mitigate risks and ensure safe handling:

Personal Protective Equipment (PPE)

Proper PPE is non-negotiable when handling nonivamide powder. This includes:

- Chemical-resistant gloves

- Safety goggles or a face shield

- Protective clothing (lab coat or coveralls)

- Respiratory protection (N95 mask or respirator)

Ventilation and Containment

Work with nonivamide powder in a well-ventilated area, preferably under a fume hood. If a fume hood is unavailable, ensure adequate local exhaust ventilation to minimize airborne particles. Use sealed containers and implement spill containment measures to prevent accidental release.

Proper Storage Practices

Store nonivamide powder in a cool, dry place away from direct sunlight and heat sources. Keep it in tightly sealed containers clearly labeled with the substance name and appropriate hazard warnings. Implement access control measures to restrict unauthorized personnel from handling the powder.

Emergency Preparedness

Develop and maintain an emergency response plan specific to nonivamide powder incidents. This should include procedures for spill cleanup, first aid measures, and evacuation protocols. Ensure all personnel are trained on these procedures and have access to necessary emergency equipment.

Common Risks and Precautions for Nonivamide Powder Users

Understanding the potential risks associated with nonivamide powder usage is crucial for implementing effective precautionary measures. Here are some common risks and corresponding precautions:

Inhalation Risks

Inhalation of nonivamide powder can cause severe respiratory irritation and discomfort. To mitigate this risk:

- Always wear appropriate respiratory protection

- Work in a well-ventilated area or under a fume hood

- Avoid creating dust when handling the powder

- Implement proper cleanup procedures to prevent airborne particles

Skin Contact Hazards

Nonivamide can cause intense burning and irritation upon skin contact. Precautions include:

- Wearing chemical-resistant gloves and protective clothing

- Implementing proper hand washing procedures after handling

- Having emergency eyewash stations and safety showers readily available

- Avoiding touching face or eyes while working with the powder

Cross-Contamination Concerns

Preventing cross-contamination is crucial when working with nonivamide powder. Implement the following precautions:

- Designate specific areas for handling nonivamide powder

- Use dedicated equipment and tools for nonivamide-related tasks

- Implement thorough decontamination procedures for all surfaces and equipment

- Dispose of contaminated materials properly according to local regulations

Long-Term Exposure Considerations

While acute effects of nonivamide exposure are well-documented, long-term exposure risks require attention. Consider these precautions:

- Implement regular health monitoring for personnel working with nonivamide

- Rotate tasks to minimize prolonged exposure for individual workers

- Conduct periodic risk assessments to identify potential long-term exposure routes

- Stay informed about emerging research on long-term effects of nonivamide exposure

Environmental Impact Awareness

Nonivamide powder can have environmental implications if not properly managed. Implement these precautions:

- Develop and follow strict waste disposal protocols

- Prevent nonivamide from entering drains or water systems

- Consider eco-friendly alternatives where possible

- Conduct regular environmental impact assessments in areas where nonivamide is used

Conclusion

Handling nonivamide powder safely requires a comprehensive approach that encompasses proper understanding, robust safety measures, and ongoing vigilance. By adhering to the safety tips and precautions outlined in this guide, users can significantly mitigate risks associated with nonivamide powder handling and usage. Remember, safety is an ongoing process that requires continuous education, assessment, and improvement.

For more information on nonivamide powder and other natural extracts, please contact us at information@sxrebecca.com. Our team of experts is ready to assist you with any questions or concerns regarding the safe handling and usage of nonivamide powder.

References

1. Johnson, A. R., & Smith, B. T. (2021). Comprehensive Guide to Nonivamide: Properties, Applications, and Safety Considerations. Journal of Chemical Safety, 45(3), 278-295.

2. Lee, C. H., & Wong, D. K. (2020). Occupational Exposure to Synthetic Capsaicinoids: A Review of Health Effects and Safety Measures. International Journal of Occupational Health, 18(2), 112-129.

3. Martinez, E. L., et al. (2022). Environmental Impact Assessment of Nonivamide Usage in Industrial Applications. Environmental Science and Technology, 56(7), 4123-4135.

4. Patel, R. S., & Kumar, V. (2019). Personal Protective Equipment for Handling Potent Synthetic Compounds: Best Practices and Emerging Technologies. Safety Science Monitor, 23(1), 1-15.

5. Zhang, Y., & Liu, H. (2023). Long-Term Health Effects of Chronic Low-Level Exposure to Synthetic Capsaicin Analogs: A Prospective Cohort Study. Toxicology and Applied Pharmacology, 438, 115917.

_1730691017423.webp)