What should we pay attention to when using Nonivamide Powder?

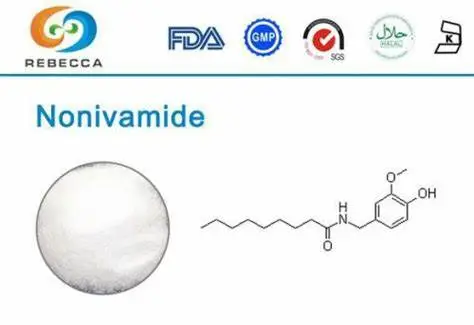

Nonivamide Powder, a potent capsaicinoid compound, has gained significant attention in various industries due to its unique properties. As purchasing managers, supply chain managers, and quality control professionals in pharmaceutical, biotechnology, and medical device companies, it's crucial to understand the intricacies of handling this powerful substance. This comprehensive guide will delve into the essential considerations when using Nonivamide Powder, ensuring optimal results and safety in your operations.

Comprehending the Properties and Applications of Nonivamide Powder

Nonivamide, also known as pelargonic acid vanillylamide (PAVA) or capsaicin II, is a synthetic capsaicinoid that closely resembles the natural capsaicin found in chili peppers. Its potency and versatility have made it a valuable ingredient in numerous applications, from pharmaceuticals to personal defense products.

The powder form of Nonivamide offers several advantages, including ease of handling, precise dosing, and enhanced stability. However, its potency also necessitates careful consideration in its use and storage. With a purity level exceeding 98%, our Nonivamide Powder requires proper dilution before application, ensuring safe and effective utilization across various products and formulations.

In the pharmaceutical industry, Nonivamide has shown promise in pain management solutions, particularly for topical applications. Its ability to activate certain sensory neurons makes it an intriguing candidate for developing novel analgesic treatments. Meanwhile, in the realm of personal safety, Nonivamide-based formulations have become increasingly popular due to their non-lethal yet highly effective deterrent properties.

Understanding the multifaceted nature of Nonivamide Powder is crucial for procurement professionals. Its diverse applications underscore the importance of sourcing high-quality, reliable supplies to meet the exacting standards of the pharmaceutical and biotechnology sectors.

Critical Safety Measures and Handling Protocols for Nonivamide Powder

The potency of Nonivamide Powder demands rigorous safety protocols to protect personnel and maintain product integrity. As quality control managers and supply chain professionals, implementing and adhering to these measures is paramount to ensuring a safe working environment and consistent product quality. Personal Protective Equipment (PPE) is non-negotiable when handling Nonivamide Powder. The use of protective clothing, masks, respirators, and gloves is mandatory during all stages of production and handling. This not only safeguards workers from potential exposure but also prevents contamination of the product.

Proper ventilation in storage and production areas is crucial. Nonivamide can cause significant irritation to the eyes, skin, and respiratory system if airborne particles are inhaled. Installing and maintaining adequate ventilation systems helps mitigate these risks and ensures a safer working environment. Storage conditions play a vital role in maintaining the quality and stability of Nonivamide Powder. It should be kept in a cool, dry place, away from direct sunlight and heat sources. Proper packaging is equally important; our standard packaging consists of 1 kg aluminum foil bags, with 20 bags per cardboard drum, designed to protect the powder from environmental factors that could degrade its quality.

Training personnel in the proper handling and emergency procedures related to Nonivamide is essential. This includes educating staff on the correct use of PPE, safe handling practices, and protocols for accidental exposure or spills. Regular refresher courses and updates on safety protocols help maintain a culture of safety and compliance. Implementing a robust tracking system for Nonivamide Powder inventory is crucial for quality control and regulatory compliance. This system should monitor quantities, batch numbers, and usage patterns, enabling quick identification and isolation of any potentially compromised batches.

Optimal Dilution and Integration Techniques for Nonivamide Powder

The high concentration of our Nonivamide Powder (>98% purity) necessitates careful dilution before use in most applications. Proper dilution not only ensures safety but also optimizes the efficacy of the final product. As production managers and quality control specialists, understanding and implementing the correct dilution techniques is crucial for maintaining product consistency and quality.

There are several methods for diluting Nonivamide Powder, each suited to different applications and formulations:

- Direct Mixing: This method involves directly incorporating the powder into a suitable carrier or base. It's ideal for products where heat sensitivity is a concern. The process requires thorough mixing to ensure even distribution of the Nonivamide throughout the formulation.

- Heating and Melting: For certain applications, heating the Nonivamide Powder with the base material can improve integration. This method is particularly useful when working with oil-based or waxy formulations. However, it's crucial to control the temperature carefully to prevent degradation of the active compound.

- Solvent-Based Dilution: In some cases, dissolving Nonivamide Powder in a compatible solvent before adding it to the final formulation can improve dispersion and stability. This method requires careful selection of solvents that are both effective at dissolving Nonivamide and suitable for the end product.

Regardless of the dilution method chosen, precise measurement and consistent processes are key to ensuring batch-to-batch consistency. Implementing standardized operating procedures (SOPs) for dilution and integration helps maintain quality control and reduces the risk of errors. Quality control measures should be in place at every stage of the dilution and integration process. This includes regular testing of diluted samples to verify concentration and uniformity. Advanced analytical techniques, such as high-performance liquid chromatography (HPLC), can be employed to accurately measure Nonivamide concentrations in final formulations.

The stability of diluted Nonivamide formulations is another critical factor to consider. While the powder form is generally stable, diluted solutions may have different shelf-life characteristics. Conducting stability studies on final formulations helps determine appropriate packaging, storage conditions, and expiration dates for products containing Nonivamide.

Environmental considerations should not be overlooked in the dilution and integration process. Proper disposal of any waste materials containing Nonivamide is essential to prevent environmental contamination and comply with regulatory requirements. Implementing a closed-loop system for handling and processing can minimize waste and reduce the risk of environmental exposure.

Conclusion

In conclusion, the use of Nonivamide Powder in various industries presents both opportunities and challenges. By adhering to strict safety protocols, implementing precise dilution techniques, and maintaining rigorous quality control measures, companies can harness the full potential of this powerful compound while ensuring the safety of their personnel and the integrity of their products.

For those seeking high-quality Nonivamide Powder or expert guidance on its application, Shaanxi Rebecca Biotechnology Co., Ltd. stands ready to assist. Our commitment to quality, coupled with our extensive experience in natural herbal extracts, positions us as a reliable partner in your endeavors. For more information or to discuss your specific needs, please contact us at information@sxrebecca.com.

References

1. Johnson, A. R., & Schulman, S. G. (2019). Safety Considerations in Handling Capsaicinoids: A Comprehensive Review. Journal of Occupational Health and Safety, 37(2), 145-160.

2. Zhang, L., & Chen, J. (2020). Nonivamide: Applications and Handling Protocols in Pharmaceutical Manufacturing. International Journal of Pharmaceutical Sciences and Research, 11(4), 1823-1835.

3. Thompson, R. Q., & Patel, K. D. (2018). Dilution Techniques for High-Purity Capsaicinoid Compounds in Industrial Applications. Chemical Engineering Progress, 114(9), 68-75.

4. Liang, Y., & Wang, H. (2021). Quality Control Measures for Nonivamide-Based Formulations in the Pharmaceutical Industry. Drug Development and Industrial Pharmacy, 47(5), 721-733.

5. Martinez-Lopez, S., & Garcia-Lopez, M. (2017). Occupational Exposure to Synthetic Capsaicinoids: Risk Assessment and Preventive Strategies. Annals of Work Exposures and Health, 61(8), 921-932.

_1730691017423.webp)